HELICAL RACK

and pinion

A helical rack is a type of gear consisting of a rack and pinion used to convert rotational motion into linear motion. These gears are commonly found in automobiles and are also popular in industrial Settings such as forklifts and power shovels.

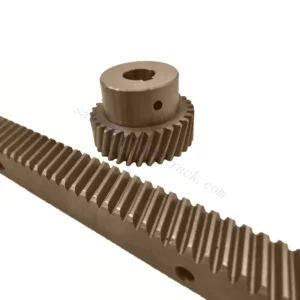

Helical Gear Rack and Pinion

Helical gear rack and pinion gears are used to convert rotation into linear motion. The flat, toothed part is the rack and the gear is the pinion. A piston coaxial to the rack provides hydraulic assistance force, and an open centered rotary valve controls the assist level.

Helical gear rack and pinion gears system is composed of two gears. The normal round gear is the pinion gear and the straight or flat gear is the rack. The rack has teeth cut into it and they mesh with the teeth of the pinion gear.

High Precision

Helical gear rack and pinions are mechanical gear components that convert rotary motion into linear motion. High precision Helical Gear Teeth, on both the Rack and Pinion, provide smooth and quiet linear motion.

Retain Power

The most common reason to change ring and pinion ratios from the original equipment is to retain power when bigger tires are put on a vehicle.

Helical Rack And Pinion Gear Types

Rack and pinion helical gear is available in three variations:

- Straight teeth have the tooth axis parallel to the axis of rotation. Straight teeth that run parallel to the axis of the gear. Load movement or transfer is manual or walk-behind.

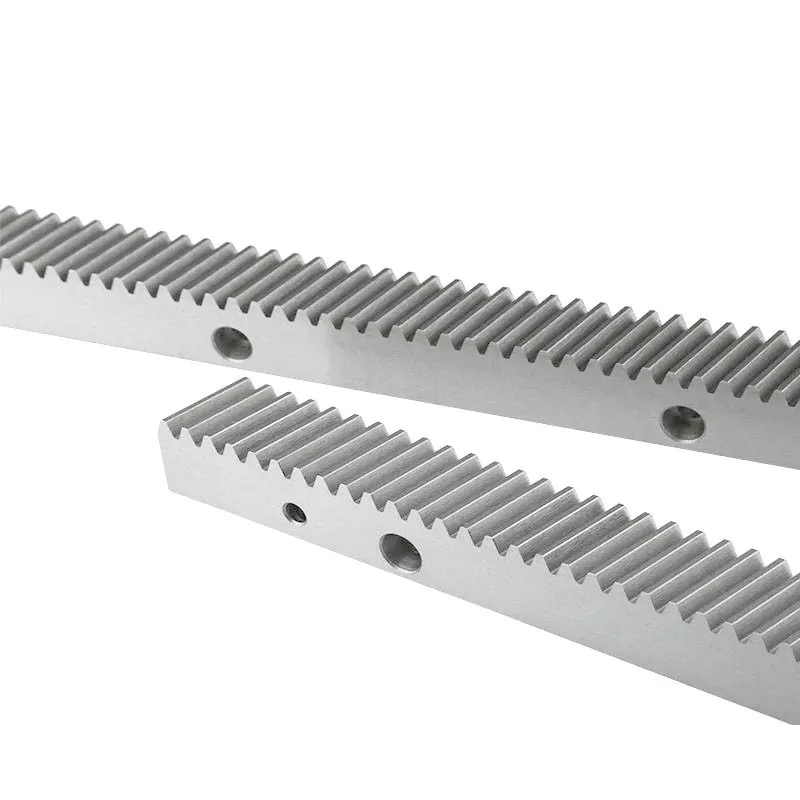

- Helical teeth gears provide continuous engagement along the tooth length and are often quieter and more efficient than straight tooth gears. Helical tooth gears resemble spur gears in the plane of rotation, but include teeth that are twisted along a helical path in the axial direction.

- Roller pinion drives use bearing supported rollers that mesh with the teeth of that rack in orderto provide minimal to no backlash.

Helical Racks Gallery

High precision helical gear teeth, on both the rack and pinion, provide smooth and quiet linear motion.

Helical Vs Straight Rack And Pinion

Helical versus Straight: The helical style provides several pretty benefits over the straight style, including: They run quieter than the straight, especially at high speeds. They have a higher contact ratio (the number of effective teeth engaged) than straight, which increases the load carrying capacity.

Precise . Quality . Trust

Our company also has other types of helical rack and pinion, if you need please contact us.

Helical Rack and Pinion Advantages

The helical rack and pinion steering system have a simple design that is just as compact as its transmission efficiency is high.

High Efficiency

Since it consists of fewer parts, the wear points are fewer and so the risks of friction are reduced.

The implication is that rack and pinion repair will be fewer and far between.

Fewer Repair

The helical rack pinion steering systems’ price is low ,because it has fewer parts with low manufacturing costs and is relatively easy to produce.

Low Cost

Helical Rack And Pinion VS Ball Screw

Ball screws can swing and vibrate over longer lengths as they hang between the ends. Helical racks are mounted directly on the precision machined steel frame/resting on a machined ledge, and therefore, do not vibrate.Helical gear rack and pinion drives give the best of both worlds – high accuracy, minimal wear for long-term reliability, no vibration, high speed, and easy maintenance.

How Do Helical Rack and Pinion Systems Work?

With the manual system, there is a helical gear rack and pinion gear set encased in a metal tube so that both ends of the rack extend from the tube. This gear set is designed to do two things. It is built to change the revolving movement of the steering wheel into the direct motion that turns the front wheels. It is also designed to reduce the effort required to turn the wheels.

It does this by providing gear reduction. Since the pinion gear is linked to the steering shaft, the pinion gear spins and moves the rack when the steering wheel is turned. This movement is then translated to the tie rods, which cause the steering knuckles to spin on their ball joints. Ultimately, the vehicle wheels move from one side to the other depending on the direction in which the vehicle is being steered. That is for the manual option.

WHY CHOOSE US

We are one of the china’s best helical rack and pinion cnc manufacturers.We can offer a wide variety of helical rack and pinion design and different helical racks sizes.We also can provide helical rack and pinion calculations.We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us!