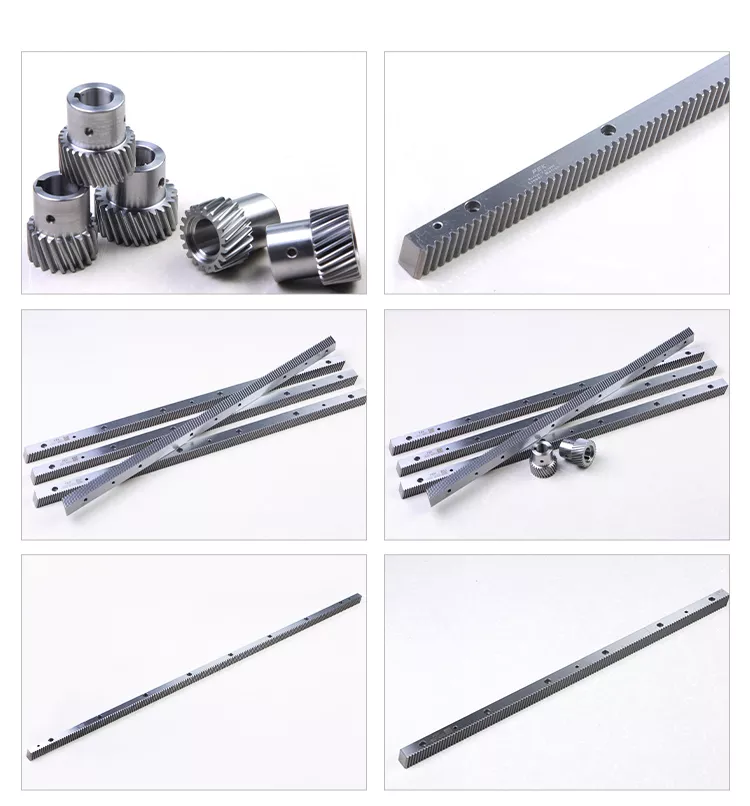

Steel Helical Rack and Pinion Gears M1.25

As one of the helical rack manufacturers, suppliers, and exporters of mechanical products, We offer helical rack and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of helical rack.

Steel Helical Rack and Pinion Gears M1.25

Our Helical Rack Finds Application In Several Industry Sectors:

The seventh axis of the robot

Truss robot mobile platform

Motion mechanisms for automated packing and packaging machines

Laser Machine

Tool and wood processing machines

The Advantage of Gear racks:

Rack and pinion drive enable the transmission of large forces and exact positioning.

Our standard gear rack length also includes 1500mm and 2000mm . We also provide customized rack service according to your

requirements.

Helical Rack and Pinion Assembly:

To assemble connected racks more smoothly, 2 ends of a standard rack would add half a tooth, which is convenient for the next half tooth of the next rack to be connected to a complete tooth. Regarding the connection of helical racks, they can be connected accurately by opposite tooth gauges.

1. When connecting racks, we recommend first locking bores on the sides of the rack and then locking bores by the foundation sequence. With assembling the tooth gauge, the pitch position of racks can be assembled accurately and completely.

2. Last, lock the rack position pins on 2 sides; the assembly is completed.

Helical Rack Specification:

|

Precision grade

|

DIN6, DIN7, DIN8, DIN10

|

|||

|

Material

|

C45 steel, Stainless steel 304, Plastic,20CrMo,40Cr, and so on

|

|||

|

Heat treatment

|

High-frequency, Quenching/Carburization improves the hardness.

|

|||

|

Surface treatment

|

Zinc-plated, Nickel-plated, Chrome-plated, Black oxide, or as you need.

|

|||

|

Application

|

Precision cutting machines. Lathes. Milling machines. Grinders. Automated mechanical systems. Automated warehousing systems.

|

|||

|

Machine

|

CNC engine lathe, milling machine, drilling machine, gear shaper, grinder, and testing center. Planer, precision CNC machining centers like Mazak, CNC lathes, DMG, etc.

|

|||

|

Workstyle

|

Execution is preferred over empty talk.

|

|||

Helical Rack and Pinion Vs Ball Screw

Ball screws can swing and vibrate over longer lengths as they hang between the ends. The spiral rack is mounted directly on the precision-machined steel frame/resting on the machined ledges and therefore does not vibrate. Helical rack and pinion drives offer our customers the best of both worlds – high precision, minimal wear for long-term reliability, no vibration, high speed and easy maintenance.

Ball screws can become a place of maintenance issues – as the ball nut rotates and moves along the ball screw, any dirt, dust and debris on the screw can collect inside the ball nut and affect the circulating ball bearing (see example picture for correct). If not cleaned regularly and correctly, ball bearings will begin to wear and stick, leading to problems in the operation of the machine.

We recommend helical rack and pinion drives for better long-term performance and easier maintenance. If the pinion wears out, it is easier and cheaper to replace than expensive ball nuts.

Helical Rack and Pinion CNC

Our in-house engineering talent has extensive expertise in motion control and is always committed to providing unmatched precision, efficiency and versatility to hobbyists and shopkeepers alike. Whatever your goals, we are committed to helping you achieve outstanding results with very little labor and cost.

Here are some of the reasons why this revolutionary CNC technology can be developed and produced:

Experienced in-house engineering talent

The ability to manufacture and test designs entirely on site

Be able to internally put designs into production

We have an unparalleled series of CNC milling machines and CNC plasma cutting machines to experience the true nature of CNC.

Helical Rack and Pinion Application

Woodworking Machine,CNC Router, High-speed Metal Cutting Machine,Pick and Place Robot,Assembly Machine,Material Handing Machine,Packaging Machine,Automaton Gantry,MachineTool,Lift Mechanisms,X-Y Axis Table,Guide Echanism,Seventh-Axis Robotic Slide.