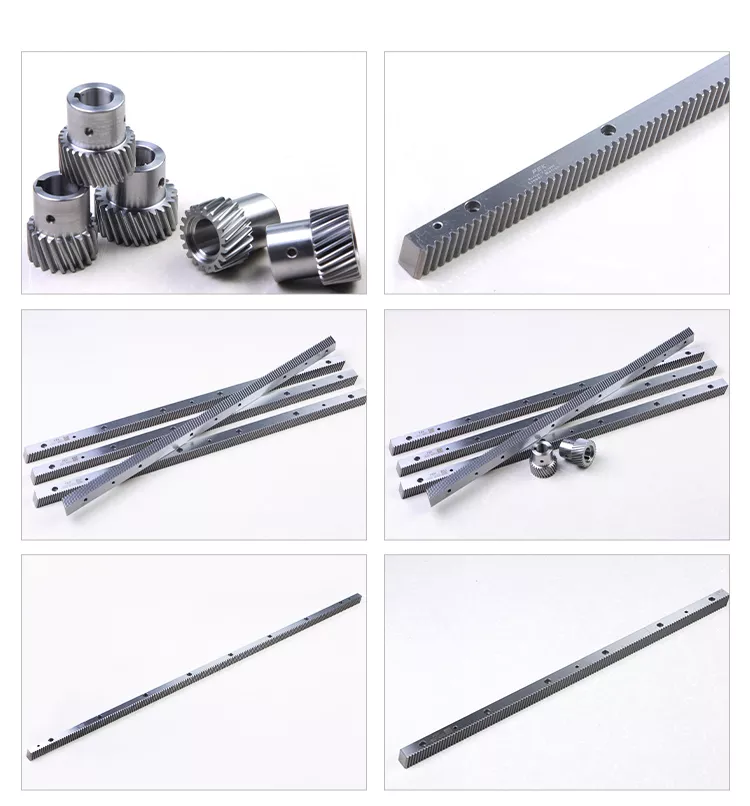

Helical Gear Rack

As one of the helical rack manufacturers, suppliers, and exporters of mechanical products, We offer helical rack and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of helical rack.

Helical Gear Rack

A helical gear rack is a type of gear consisting of a rack and pinion used to convert rotational motion into linear motion. These gears are commonly found in automobiles and are also popular in industrial Settings such as forklifts and power shovels.

The teeth of the helical gear rack and pinion are meshed together to create a right Angle of length, allowing them to effectively convert the rotary input into a linear output. This is most commonly done by applying rotational motion to a circular pinion meshed by the teeth of a rack.

A helical gear rack is a drive that transfers motion within a pinion. It is commonly used in automobile steering systems and in a variety of machines that require low noise levels, high-speed ranges, or high torque transmission along parallel axes.

A helical gear rack and pinion are available in a wide array of sizes, materials, and quality levels to meet most axis drive requirements. It’s ideal for axis drives that need precise positioning & repeatability, traveling gantries & columns, pick & place robots, CNC routers, and material handling applications.

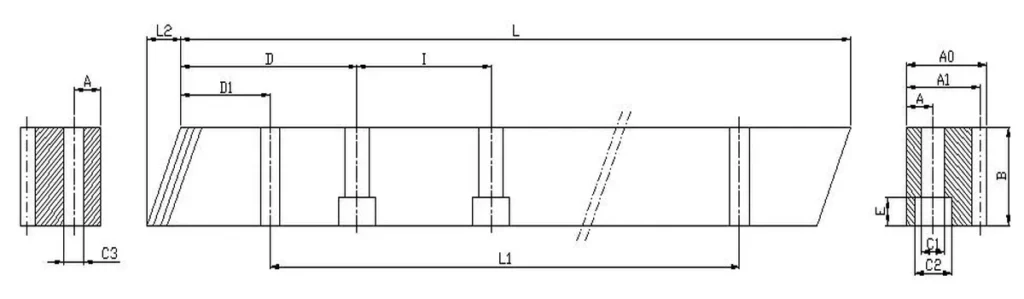

Helical Gear Rack Specification:

| Precision Grade: (JIS Grade 5) 7e25 | Hardening: Tooth area carburized(HRC42-48) |

| Material:(S45C Medium Carbon Steel)C45 | Side Ground: Included |

| Type: Helical Gear Rack | Pressure Angle: 20° |

| Treatment of Teeth: Milled | Right helix angle: 19°31′42″ |

| Module | L | L2 | Tooth No. | B | A0 | A1 | D | I | Hole No. | A | C1 | C2 | E | D1 | I1 | C3 | Pitch Error /300mm |

| 1 | 1000.00 | 3.14 | 300 | 15 | 15 | 14 | – | – | – | – | – | – | – | – | – | – | 0.02 |

| 1.5 | 1000.00 | 6.7 | 200 | 19 | 19 | 17.5 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 0.03 |

| 2 | 1000.00 | 8.5 | 150 | 24 | 24 | 22 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 0.031 |

| 2.5 | 1000.00 | 8.5 | 120 | 24 | 24 | 21.5 | 62.5 | 125 | 8 | 9 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 0.033 |

| 3 | 1000.00 | 10.3 | 100 | 29 | 29 | 26 | 62.5 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 | 0.035 |

| 4 | 1000.00 | 13.8 | 75 | 39 | 39 | 35 | 62.5 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.0 | 7.7 | 0.038 |

| 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.5 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 | 0.04 |

| 6 | 1000.00 | 20.9 | 50 | 59 | 49 | 43 | 62.5 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 | 0.042 |

| 8 | 1000.00 | 28.7 | 36 | 79 | 79 | 71 | 60 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 19.7 | 0.045 |

| 10 | 1000.00 | 35.11 | 30 | 99 | 99 | 89 | 62.5 | 125 | 8 | 32 | 33 | 48 | 32 | 125.0 | 750.0 | 19.7 | 0.052 |

Helical Gear Rack and Pinion Product Information:

| Process | Machining, Forging, Casting, Cutting |

| Material | C45(1045), A3(low carbon steel), 40Cr, 20CrMnTi, 42CrMo, Cast iron, Ductile iron, Copper, Stainless steel, and so on, as you requested |

| Heat Treatment | High-frequency quenching, Carburizing, Shot peening, Quenching, and Tempering, Nitriding |

| Surface Treatment | I am blacking, Hot-dip Galvanizing, Hard Chrome Plating, Zinc Plating, Electroplating, Nickel plating, Sandblasting, Color painting, Dacromet coating, Powder coating, and customer requirements. |

| Performance | Long lifespan, High precision, High wear resistance, High strength, Low noise, Smooth and steady, Fatigue strength |

| Model | ANSI, DIN, JIS Standard, Non-Standard, Spur Gears, Helical Gears, Straight Bevel Gears, Spiral Bevel Gears, Worm Gears, Gear Racks |

| Packaging | Products are carefully packaged, Inner plastic bags and outer carton boxes or customer requirement; after long-distance transport or long time store, open the package; brand new, no damage, no rust. |

Rack Types:

Helical gear rack and pinions are available in two variations:

- Straight teeth have the tooth axis parallel to the axis of rotation. Straight teeth that run parallel to the axis of the gear.

- Helical teeth gears provide continuous engagement along the tooth length, are often quieter and more efficient than straight tooth gears, and offer higher loading for the same rack width. Helical tooth gears resemble spur gears in the rotation plane but include teeth twisted along a helical path in the axial direction.

Number of Teeth:

The number of teeth of the spiral rack depends on the pitch diameter and spiral Angle. It is usually smaller than the number of teeth of spur gears to achieve low noise, vibration, and wear.

The tooth contact of a helical gear pair is usually rolling, but there may be slippage when engaged and disengaged. This is an important problem at the beginning of the active profile and at the end of the active profile when the involute profile enters or exits the engagement cycle.

Generally speaking, the finer the shape of the tooth, the larger the design space. Often, constraints such as the required center distance, target transmission ratio, and sum of profile displacements help limit the design space, allowing the designer to explore viable candidates more quickly.

How Helical Gear Racks Work in Rack and Pinion Machines?

Rack and pinion gears are used to convert rotational motion into linear motion. A small diameter circular gear (pinion) meshes with a bar-shaped gear (rack) stretched in a rod form.

The pinion transmits power by rotating the rack, which then moves. Both straight and helical gears are used in these systems, but helical gears are quieter and stronger.

We are one of china’s best helical rack and pinion cnc manufacturers. We can offer a wide variety of helical rack and pinion design and different helical racks sizes. We also can provide helical rack and pinion calculations. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Helical Rack and Pinion Vs Ball Screw

Ball screws can swing and vibrate over longer lengths as they hang between the ends. The spiral rack is mounted directly on the precision-machined steel frame/resting on the machined ledges and therefore does not vibrate. Helical rack and pinion drives offer our customers the best of both worlds – high precision, minimal wear for long-term reliability, no vibration, high speed and easy maintenance.

Ball screws can become a place of maintenance issues – as the ball nut rotates and moves along the ball screw, any dirt, dust and debris on the screw can collect inside the ball nut and affect the circulating ball bearing (see example picture for correct). If not cleaned regularly and correctly, ball bearings will begin to wear and stick, leading to problems in the operation of the machine.

We recommend helical rack and pinion drives for better long-term performance and easier maintenance. If the pinion wears out, it is easier and cheaper to replace than expensive ball nuts.

Helical Rack and Pinion CNC

Our in-house engineering talent has extensive expertise in motion control and is always committed to providing unmatched precision, efficiency and versatility to hobbyists and shopkeepers alike. Whatever your goals, we are committed to helping you achieve outstanding results with very little labor and cost.

Here are some of the reasons why this revolutionary CNC technology can be developed and produced:

Experienced in-house engineering talent

The ability to manufacture and test designs entirely on site

Be able to internally put designs into production

We have an unparalleled series of CNC milling machines and CNC plasma cutting machines to experience the true nature of CNC.

Helical Rack and Pinion Application

Woodworking Machine,CNC Router, High-speed Metal Cutting Machine,Pick and Place Robot,Assembly Machine,Material Handing Machine,Packaging Machine,Automaton Gantry,MachineTool,Lift Mechanisms,X-Y Axis Table,Guide Echanism,Seventh-Axis Robotic Slide.