Helical Rack For Material Handling Industry

As one of the helical rack manufacturers, suppliers, and exporters of mechanical products, We offer helical rack and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of helical rack.

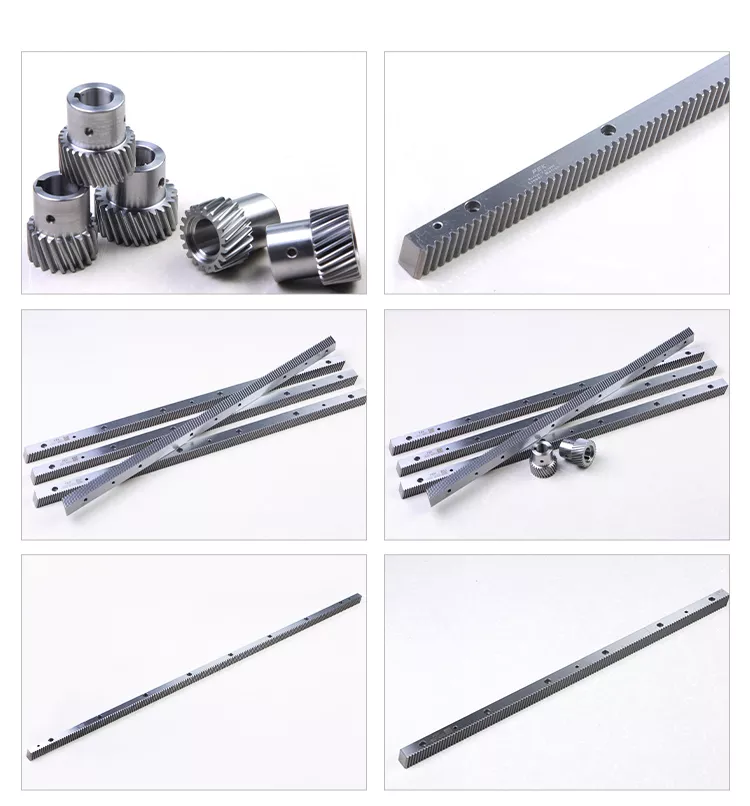

Helical Rack For Material Handling Industry

A helical rack is a type of gear consisting of a rack and pinion used to convert rotational motion into linear motion. These gears are commonly found in automobiles and are also popular in industrial Settings such as forklifts and power shovels.

The teeth of the rack and pinion are meshed together to create a right Angle of length, allowing them to effectively convert the rotary input into a linear output. This is most commonly done by applying rotational motion to a circular pinion meshed by the teeth of a rack.

There are three basic types of rack and pinion gear sets: straight, helical, or spur. Each has its own advantages and disadvantages, but in general, helical or spur gears offer greater efficiency and quieter operation than their straight-toothed counterparts.

Helical Rack Specification:

The backlash of Helical Rack:

Rack and pinion drives are popular in machine tools, moving gantries and columns, take-and-place mechanisms, CNC routers and material handling systems. They provide straight-line motion and are economical over long distances.

The pinion and rack need a certain amount of clearance in order to engage properly. This can lead to a rebound, which is a twisted gear meshing.The angular clearance of a helical gear is proportional to the pitch diameter and depends on the transmission ratio. It can also be different for each gear in a grid.

Backlash can be eliminated or reduced by modifying the tooth profile of the gear. This is usually done by adding a spring or weight to the last driven gear in a series of gears.

Another approach is to use involute gear profiles, which allow center distance to vary without affecting nominal transmission ratio or conjugation. This is especially useful in high-speed, one-way drives, where bounce-back problems can occur.

Manufacturing Type of Helical Rack:

A rack is a linear driver that converts rotational motion into linear motion by meshing teeth on gears. They are most commonly used in automotive steering systems, weighing scales, and conveyor mechanisms.

They are usually made of aluminum or steel and can be coated with black oxide to prevent rust. They come in different lengths and are pre-drilled for installation.

A cutter is then used to cut the tooth frame, leaving burrs on the teeth. The burr is then removed with a deburring machine.This reduces the warping of the frame. The ends are also machined and ground so that they bump into each other.

Helical gear have a higher contact ratio than spur gears, which results in superior transmission accuracy and quieter operation. They also support larger loads due to their longer contact length.

Helical Rack and pinion Application:

Helical Rack and Pinion Vs Ball Screw

Ball screws can swing and vibrate over longer lengths as they hang between the ends. The spiral rack is mounted directly on the precision-machined steel frame/resting on the machined ledges and therefore does not vibrate. Helical rack and pinion drives offer our customers the best of both worlds – high precision, minimal wear for long-term reliability, no vibration, high speed and easy maintenance.

Ball screws can become a place of maintenance issues – as the ball nut rotates and moves along the ball screw, any dirt, dust and debris on the screw can collect inside the ball nut and affect the circulating ball bearing (see example picture for correct). If not cleaned regularly and correctly, ball bearings will begin to wear and stick, leading to problems in the operation of the machine.

We recommend helical rack and pinion drives for better long-term performance and easier maintenance. If the pinion wears out, it is easier and cheaper to replace than expensive ball nuts.

Helical Rack and Pinion CNC

Our in-house engineering talent has extensive expertise in motion control and is always committed to providing unmatched precision, efficiency and versatility to hobbyists and shopkeepers alike. Whatever your goals, we are committed to helping you achieve outstanding results with very little labor and cost.

Here are some of the reasons why this revolutionary CNC technology can be developed and produced:

Experienced in-house engineering talent

The ability to manufacture and test designs entirely on site

Be able to internally put designs into production

We have an unparalleled series of CNC milling machines and CNC plasma cutting machines to experience the true nature of CNC.

Helical Rack and Pinion Application

Woodworking Machine,CNC Router, High-speed Metal Cutting Machine,Pick and Place Robot,Assembly Machine,Material Handing Machine,Packaging Machine,Automaton Gantry,MachineTool,Lift Mechanisms,X-Y Axis Table,Guide Echanism,Seventh-Axis Robotic Slide.